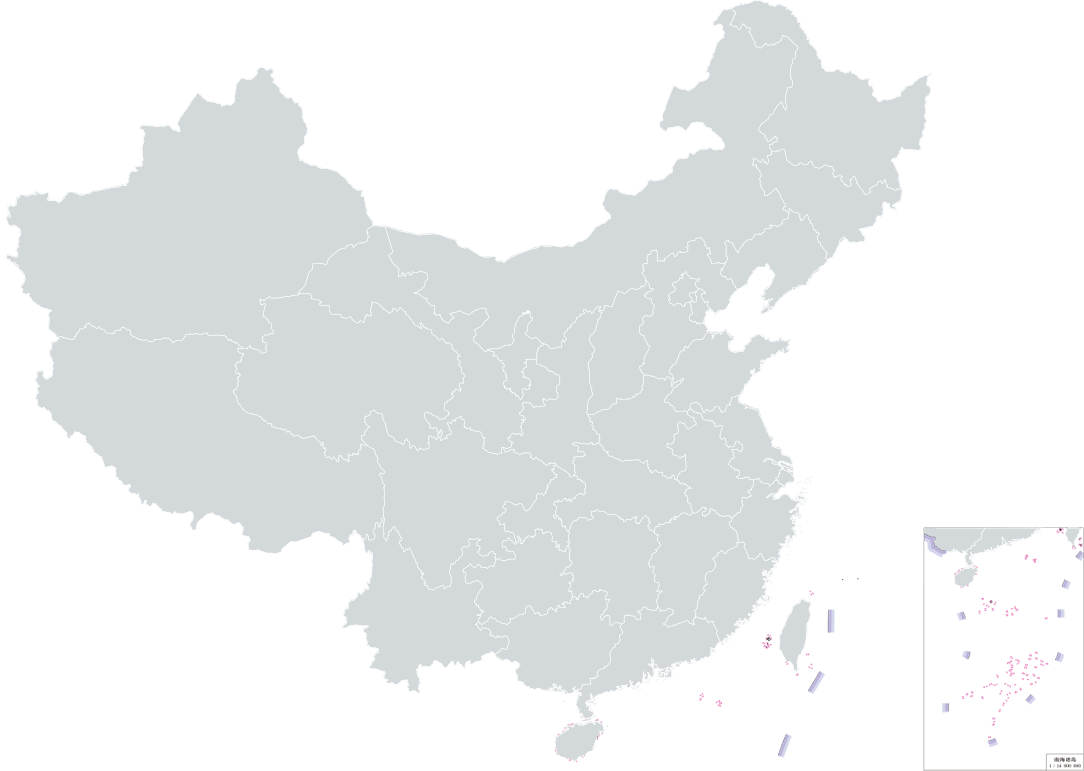

審圖號:GS(2023)2767號

自然資源部 監(jiān)制

Solution

Alsco mode

Natural network

Having been deeply involved in the industry for many years, ALSCO has formed a strong natural network based on customer needs. As a professional integrated service solution provider, our natural network plus the Internet of Things set up in forward transportation, instant recycling, reverse logistics, shared rental, and box dispatching can efficiently meet the diverse needs of customers.

The super liquidity brought by the ALSCO rental and sharing system can truly achieve the goals of increasing efficiency, reducing costs, saving energy and reducing carbon for enterprises and the world.

The super liquidity brought by the ALSCO rental and sharing system can truly achieve the goals of increasing efficiency, reducing costs, saving energy and reducing carbon for enterprises and the world.

-

- Changchun

- Dalian

- Qingdao

- Lianyungang

- Nanjing

- Suzhou

- Wuxi

- Wuhan

- Chongqing

- Fuzhou

36

Covering city

2000+

Business partner

Double circulation

Outer circulation – the dual circulation system created by ALSCO breaks the traditional reliance on disposable packaging in the world, introduces returnable and reusable high-quality packaging to the market, leads the world’s green future, and gains world-wide success in the development process unanimously recognized by high-quality enterprises.

Integrated services

Integrated service, do every step carefullyFrom design to solution integration, road testing to independent production, procurement, and operation, ALSCO has formed an intelligent analysis and scheduling system through digital unit packaging to integrate and simplify the packaging and transportation process, and accurately and strictly control every link. Our expertise is obvious to all.

Good at work

Carefully design packaging solutions, taking into account every detail, aiming to efficiently provide customers with the best packaging possibilities. After careful design by the R&D technical team, we adhere to the road test process to ensure that the actual process is as smooth as silk, avoid possible risks, and run smoothly after starting the project.

ALSCO Group has two wholly-owned manufacturing plants and vertically integrates the entire supply chain. By accurately controlling the production process, ALSCO will present the most perfect answer to customers. The quality of our care can be felt with your hands.

ALSCO Group has two wholly-owned manufacturing plants and vertically integrates the entire supply chain. By accurately controlling the production process, ALSCO will present the most perfect answer to customers. The quality of our care can be felt with your hands.

Craftsmanship

The craftsmanship spirit of ALSCO comes from our Chinese temperament. Based on our more than 20 years of experience focusing on the transportation industry, our products are of high quality and quantity; our services are immediate and timely, only for the sustainable development and popularization of the recyclable unit packaging industry.

Quality lies in action

Quality lies in action: precise control of every link reflects ALSCO's ultimate pursuit of quality. Optimizing the solution process, optimizing packaging quality, and maximizing customer benefits are the driving force for our continuous progress.

Create something new

Our technical team is constantly learning and improving, aiming to provide you with the best global packaging solutions. Whether it is product materials, solution design, or operation management, our innovation will bring lasting effects at every step.

Digital intelligent management

ALSCO invests heavily in digital technology to realize intelligent operation management: these digital technologies improve management efficiency, help ALSCO achieve precise scheduling, reduce waste, achieve lean operations, and maximize the value of existing resources, which also makes ALSCO a leader in the industry. It is in a leading position and has significant competitive advantages.We will continue to increase investment in digitalization, continuously improve management levels, and create greater value for customers: We believe that the use of digital technology will greatly change the management methods and business models of the packaging industry. This requires ALSCO to continue to explore and innovate, keep pace with the times, and grasp the digital development trend. We also hope to collaborate and communicate with more companies to jointly promote industrial change and upgrading.

IoT RPS returnable packaging management process

Lot unpackaged self-tracking system

貨主

貨物

包裝

循環(huán)包裝+貨物

運輸

循環(huán)包裝+貨物

中轉(zhuǎn)倉庫

循環(huán)包裝+貨物

開箱

貨物

工廠

資產(chǎn)全生命周期追蹤定位

實現(xiàn)物聯(lián)網(wǎng)設(shè)備在物流循環(huán)資產(chǎn)的全生命周期持續(xù)供電無需換電池

資產(chǎn)全占用與閑置狀態(tài)識別

智能托盤可感知托盤上貨物狀態(tài):裝載、運輸、卸貨、堆碼

資產(chǎn)盤點

- 每日自動盤點

- 防盜。防占用

資產(chǎn)調(diào)度運營

通過后臺大數(shù)據(jù)模型進(jìn)行全網(wǎng)智能調(diào)度,實現(xiàn)出庫、入庫、上線、下線、裝箱、拆箱的狀態(tài)識別

物流運輸風(fēng)險檢測(可選)

- 監(jiān)測貨物運輸過程風(fēng)險

- 監(jiān)測物流運輸倉儲風(fēng)險

loT RPS適應(yīng)不通場景的智能模塊

針對不同的包裝資產(chǎn)器具提供不同的智能模塊進(jìn)行業(yè)務(wù)適配

Digital intelligence value

Interface with customer systems to share packaging operation data to achieve collaborative management and further improve resource utilization.

Enhance big data analysis capabilities, establish packaging operation models, conduct simulation experiments, discover operational risks in advance, and guide management decisions.

Continue to iterate tracking technologies such as RFID and BLE to expand the scope of monitoring, generate more accurate and detailed packaging operation data, and discover more operational opportunities.

Develop a packaging operation monitoring and early warning system and use artificial intelligence technology to achieve real-time early warning of abnormalities and reduce operational losses.

Digital means continue to advance, gradually realizing driverless forklifts, AGV automatic handling, etc., reducing manual operations and improving work efficiency.